Hammer fix

Lately I’ve noticed with 25 Vulcan the 40-50 and beyond yard shots where not slam dunk anymore. Well this morning after a horrendous outing I figured I’d better look into it.

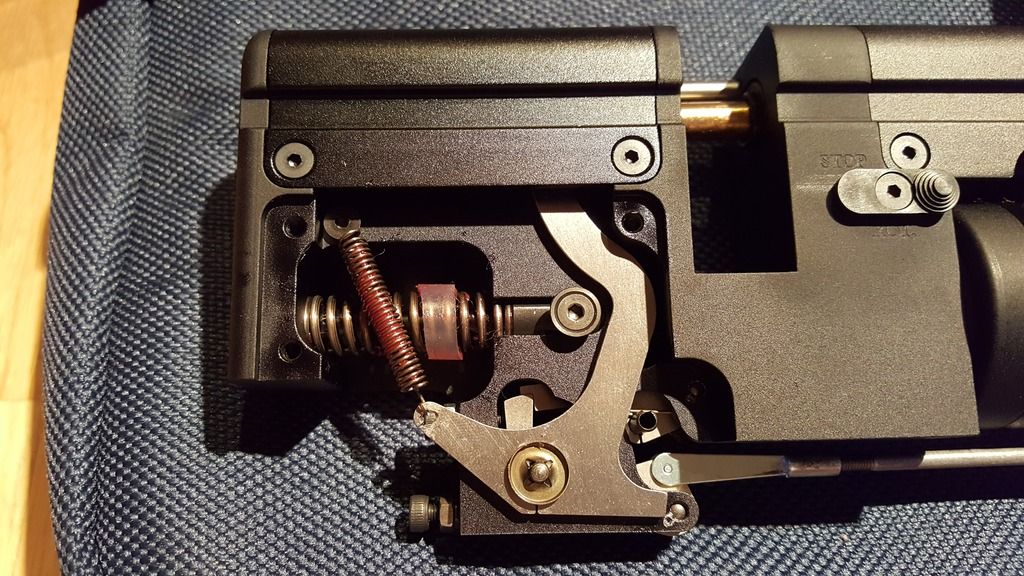

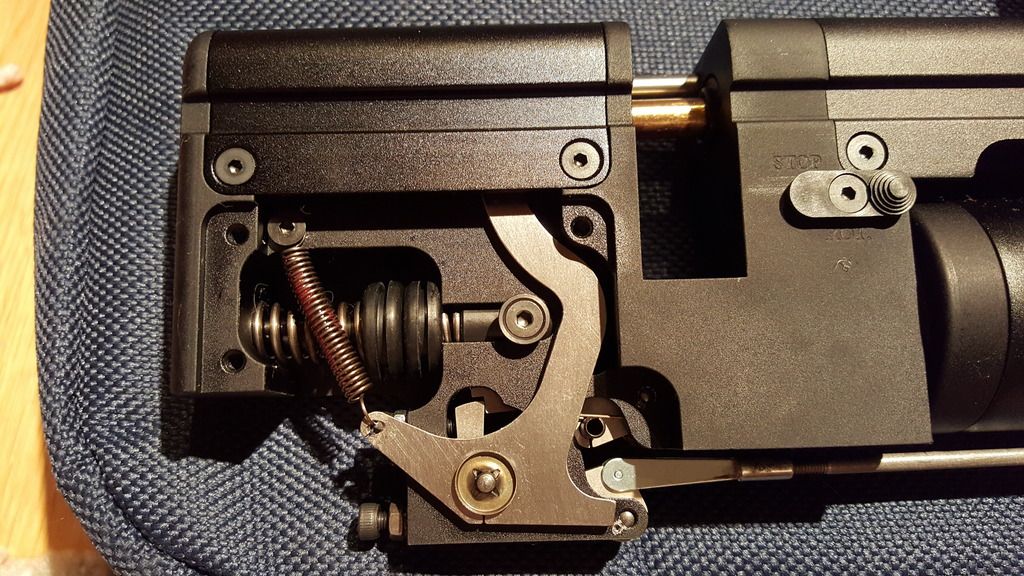

I whipped out chronograph and viola the answer was clear. First it was shooting 880-990 to start off with. Last time I checked it was 930 or so. So I took your the hammer screw and was able to move velocity around but not consistent at all. Extreme spread was 25 and then some. My 80 yard groups showed it too. So I took it apart but had to reverse drill out two of the screws holding the side plate. (thanks Zonk for the 2 spares you sent me) I took hammer out and wiped it clean. Then I noticed the one end where trigger catches hammer was sharp. So I smoothed out the edges using a drill to spin hammer and taking some cloth to the edge.

While I had it apart I figured I might try to do something with hammer spring too

I put it to the test through chrony and settled for 920 with es of 2 with 20 shots tethered to my tank. Major improvement to say the least.

I went and did a accuracy test and it puts 3 pellets through a hole not much bigger than the pellet at 50 yards.

I’m so happy to have my Vulcan back to its usual self.

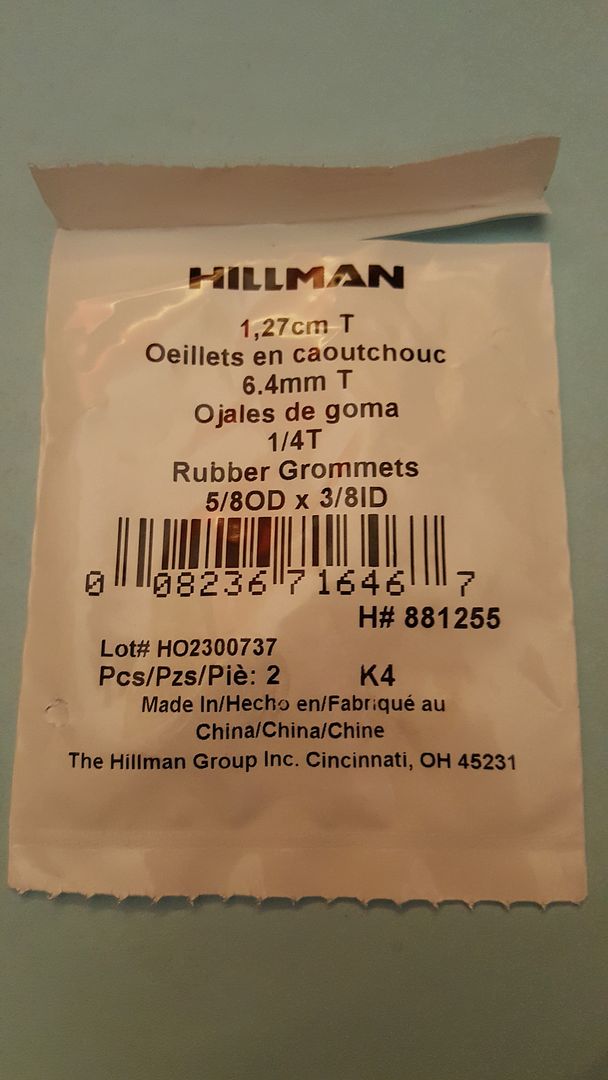

The piece on the spring is a rubber grommet that you use to insulate a hole to pull wires through. I can’t hear the spring at all. Problem is my gun got louder. Lol

Sent from my Z30 using Tapatalk

All Replies

- You must be logged in to reply to this topic.

:hoot:

That Silver Colibri is one sweet instrument!!!

Hoot: